U.S. ITER Central Solenoid Module Equipment

Springs Fabrication is proud to have been selected to provide several key pieces of equipment for their purpose-built Central Solenoid Manufacturing Facility (CSMF) in support of their project to produce the ITER central solenoid. Equipment provided:Coil Support and Lifting Frame (CSLF) –The CSLF was provided as a turn-key product including detailed engineering and design, material procurement, manufacturing, assembly and functional acceptance testing at facility and on-site validation. The functional acceptance test included successfully lifting 283,000 lbs. within the required parameters. Turn Insulation Station. At this station, the 110-metric-ton module is lifted, a...

Read More

Epicenter Sculpture - Weidner Field

Based on Custom Metal Fabrication specialties, Springs Fabrication was contracted by the partnership of Switchbacks Football Club and Weidner Apartment Homes to design, manufacture, erect, and commission the sculpture to anchor the entrance on the Northeast corner of Weidner Field, the home stadium for the Switchbacks FC.The sculpture, a massive structure weighing more than 164,000 pounds at 35-ft. tall and with a diameter of 65-ft, is made of highly polished stainless steel and required over 20,000-man hours to complete. Springs Fabrication worked with partners Perkins & Will and Martin/Martin Consulting Engineers to accomplish the incredible engineering feat that is the Epicenter.The E...

Read More

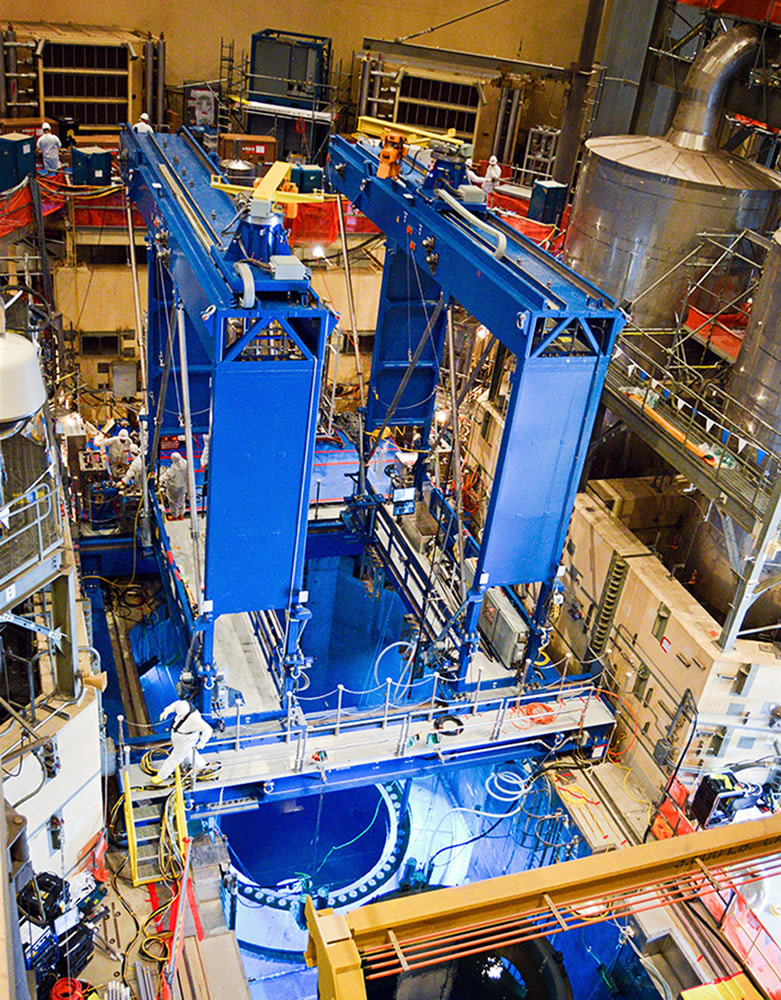

Water Jet Peening Bridge System

Springs Fabrication was awarded the Water Jet Peening Bridge System in support of our customers project with Wolf Creek Nuclear Operating Corporation and Mitsubishi Heavy Industries subsidiary, Mitsubishi Nuclear Energy Systems (MNES), to perform water jet peening of the reactor vessel components susceptible to primary water stress corrosion cracking (PWSCC) during the plant’s next refueling outage. The Water Jet Peening Bridge System was designed and fabricated to minimize crane use over the reactor cavity during the peening operation. The modular, 90-ton bridge assembly was fabricated, inspected, tested, assembled and prepared for shipment at our facility.Learn more about this project (N...

Read More

Rotary Dryer

Springs Fab and our customer worked together to redesign and supply an 8ft diameter by 45ft long rotary dryer shell for the end user. The end user dries a variety of grades of metallurgical coke, primarily for the steel industry. The product that is processed in the dryer is extremely abrasive. The end user had purchased a used rotary dryer in the earlier 90`s. Springs Fab worked with our customer to complete the detailed design with several improvements and fabricated a replacement dryer, shop assembled it for testing and then shipped to the site for installation. Several years later Springs Fab and our customer repeated to process to replace the shell a second time with additional improvem...

Read More

Flotation Cells

Springs Fabrication was awarded twelve (12) Flotation Cells in support of a project in Bagdad, Arizona to process Copper Ore for mining operations. The flotation cells were completely processed, fabricated and tested at our facility. The flotation cells were approximately 26’ in diameter. To allow for economical shipment these cells were fabricated from four 180-degree sections that bolted together. Our scope of work included development of fabrication drawings, drive platforms, stator assembly, dart valves and complete mechanical assembly of the cells and then integrated functional testing of the mechanical systems....

Read More

Sound Mitigation Walls

Springs Fabrication was awarded the first of multiple ongoing contracts to design, engineer and manufacture a new Temporary Sound Wall product in support of a well site sound mitigation product line. The collapsible wall sections, 20’ wide x 32’ high when extended, were designed to achieve specific structural and environmental requirements for ease of installation, transportation and in-service use. The walls were fabricated and inspected in accordance with AWS D1.1. In Springs Fabrication has manufactured over five (5) miles of the sound wall. Springs Fabrication designed and manufactured specialized fixtures and developed dedicated work cells for fabrication and assembly operations t...

Read More

Stabilization and Knock Out Skids

This condensate gas project was critical to one of our oil and gas customers to ensure their compliance with EPA limits on emissions. This project was a short lead time order with strict delivery requirements. Springs Fabrication was awarded this project because of our proven ability to produce multiple process skids within a compressed delivery schedule. This effort included in-house skid design and engineering through final assembly and testing of modular plug-and-play process skids. The one-stop-shop capability provided significantly reduced lead times and allowed our customer to meet tight deadlines without sacrificing quality or functionality....

Read More

Julie Penrose Fountain

Working closely with the artist, the architect and the City of Colorado Springs, Springs Fabrication produced a striking 50-ft. tall continuum sculpture that is 45-ft. in diameter and is made of 24 tons of stainless steel and carbon steel. The structure is a helical shape with a triangular cross section which presented some real challenges in both design and construction. It sits on an 18-ft. x 6-ft. diameter base that is powered by an electric motor which rotates the fountain at 4 revolutions per hour. The sculpture is part of the fountain, producing a curtain of water through the use of 366 water nozzles. The fountain was dedicated on June 7, 2007, to Julie Penrose a local philanthropist a...

Read More

Furnace Vacuum Vessel

Springs Fabrication manufactured several Vacuum Furnace Vessels throughout the years. These vessels were designed, engineered and stamped to the requirements of ASME Section VIII, Division 1 for both positive pressure and full vacuum. These vacuum furnace vessels were processed, fabricated, coated and tested at our facility. The vessels, made from carbon steel, are approximately 13ft diameter x 30ft overall height, fully jacketed, with O-ring grooved body flanges and internal shunts. The body flanges were machined in-house....

Read More

Tunnel Liner and Diverter System

This water utility project was in support of the Southern Delivery System (SDS). Coordinating with several government agencies, Springs Fabrication generated 3D models and fabrication drawings from provided design to verify the fit and fabrication details required to facilitate successful interface with existing dam structures. The 3D models were able to identify interferences that were addressed and remedied prior to fabrication. This critical verification activity eliminated future schedule delays and additional costs that would have been experienced at the site. This project required strong expertise in welding and large machining to manufacture the components from carbon and stainless st...

Read More

Inlet Gas Scrubber Vessel

One of our large global customers partnered with Springs Fabrication in the early design phase of their project to collaborate on a vessel that required a flexible and swift design. Equally important were the fabrication resources needed to meet a critical delivery date that coincided with a plant shut down. Our customer leveraged our expertise in the adherence to extensive and complex specifications that was required to design and fabricate their product. This project included comprehensive non-destructive examinations (NDE) prior to and after post weld heat treat (PWHT) including, wet fluorescent magnetic particle examination (MT), ultrasonic examination (UT) and full true tube radiography...

Read More

Ion Specific Media (ISM) System

Sometimes an unplanned event comes along that must be handled immediately, whatever it takes. After an earthquake and subsequent tsunami caused the failure of the Fukushima power plant in Japan, Springs Fabrication quickly became involved in an intense effort to design and build an ion exchange system to process the water used to cool the damaged power plant`s reactor. Coordinating efforts with two other Fabricators across the country, Springs Fabrication lead the design initiative and manufacture of the ion exchange vessels and process skids. The time to market on this project was only four weeks from initial client meeting to first shipment. Our dedicated team of craftsmen and professional...

Read More

NIST VSANS Pre-Sample Vacuum Chamber

Springs Fabrication was awarded the NIST VSANS (Very-Small-Angled-Neutron-Scattering) Chamber from our customer in support of their contract with the Neutron Research Lab at NIST in Gaithersburg, Maryland. The vacuum chamber was completely processed, fabricated and tested at our facility. The 75-ft long completed chamber consisted of eleven individual 6061 aluminum chamber sections bolted together. All o-ring sealing surfaces were machined on our large horizontal boring mill utilizing a single set up. The chambers were mounted on concrete filled fabricated steel stanchions. The assembly process included thoroughly cleaning the chambers, bolting and sealing the chambers, inspection and testi...

Read More

Yard Bogie

Springs Fabrication recently completed the design, engineering, and full-scale production of eleven custom Yard Bogies to support a major client in the wind energy sector. These robust transport systems were specifically developed to facilitate the movement of large wind tower sections within a manufacturing environment. Each Yard Bogie was engineered with a 50-ton load capacity, ensuring the safe and efficient handling of massive structural components during assembly and staging. Our in-house team meticulously managed the entire lifecycle of the project—from raw material processing to final assembly—within our state-of-the-art manufacturing facility. Constructed from carbon st...

Read More

Effluent Tanks

Springs Fabrication successfully completed the design, fabrication, and delivery of two custom Effluent Tanks for a prominent National Laboratory. These tanks were engineered to API-620, the industry standard for large, welded, low-pressure storage tanks, ensuring long-term reliability and safe containment of effluent liquids. Each tank features a capacity of approximately 11,000 gallons, with dimensions of 12 foot outside diameter and 8 foot in side shell height. Designed for high-integrity containment in a demanding laboratory environment, the tanks were constructed using 304/L stainless steel for all wetted parts, offering excellent corrosion resistance and compatibility with a rang...

Read More